The term embedded copper busbar PCB may sound complicated at first, but it represents one of the most important innovations in modern power electronics. When electronic devices require high current, stable heat dissipation and long-term reliability, traditional PCBs reach their limits. This is where embedded copper technology comes into play.

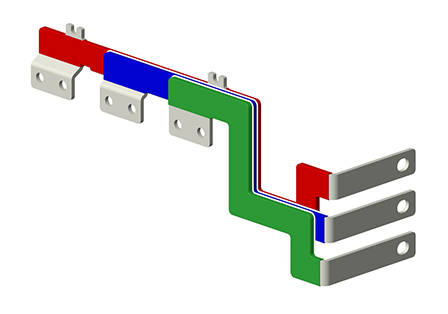

Embedded copper busbar PCBs integrate solid copper blocks directly within the board structure. These copper sections conduct heat and current much more efficiently than regular copper foil traces. The result? Improved thermal management, reduced voltage drop, and increased power density — all in a compact design.

At Best Technology, we have spent years perfecting this technology, combining precision engineering with advanced lamination and drilling techniques. The goal is simple: help engineers design safer, more durable high-power PCBs for demanding industries such as automotive, renewable energy, power control and aerospace.

What is Embedded Copper Busbar PCB?

An embedded copper busbar PCB is a circuit board containing copper blocks inserted into specific regions on a substrate. These copper strips act as internal conductors, transferring electrical current and heat more effectively than standard copper traces.

In contrast to conventional designs that rely on thin copper layers, embedded copper PCBs use thick copper plates or bars, which can be several millimeters thick. These copper elements sit flat or slightly raised within the board structure, connecting directly to high-power components such as MOSFETs, IGBTs, or power modules.

Essentially, this technology bridges the gap between traditional PCBs and metal busbars, combining the flexibility of PCB design with the strength of heavy-duty copper.

How Does the Embedded Copper Process Work?

The manufacturing process involves embedding blocks of copper into pre-cut slots within the PCB core. During lamination, the resin fills the small gaps between the copper and the surrounding substrate. Once cured, the copper becomes a permanent part of the board.

Here’s a simplified breakdown of the steps:

1. Slot Milling: Precise cavities are milled into the PCB core to hold the copper blocks.

2. Copper Block Preparation: Copper pieces are polished, cleaned, and sometimes wire cut to obtain small or intricate shapes.

3. Brown Oxide Treatment: The copper surface undergoes oxidation to increase adhesion.

4. Lamination: The layers are stacked with high resin PP sheets, then pressed under heat and pressure to bond the copper inside.

5. Drilling & Coating: Holes are drilled, lined, and checked to maintain alignment and connectivity.

The embedded copper is now part of the circuit structure, providing a solid thermally conductive path between components.

Fully Embedded Copper Busbar PCB vs. Semi-Embedded

There are two main configurations of embedded copper busbar PCBs:

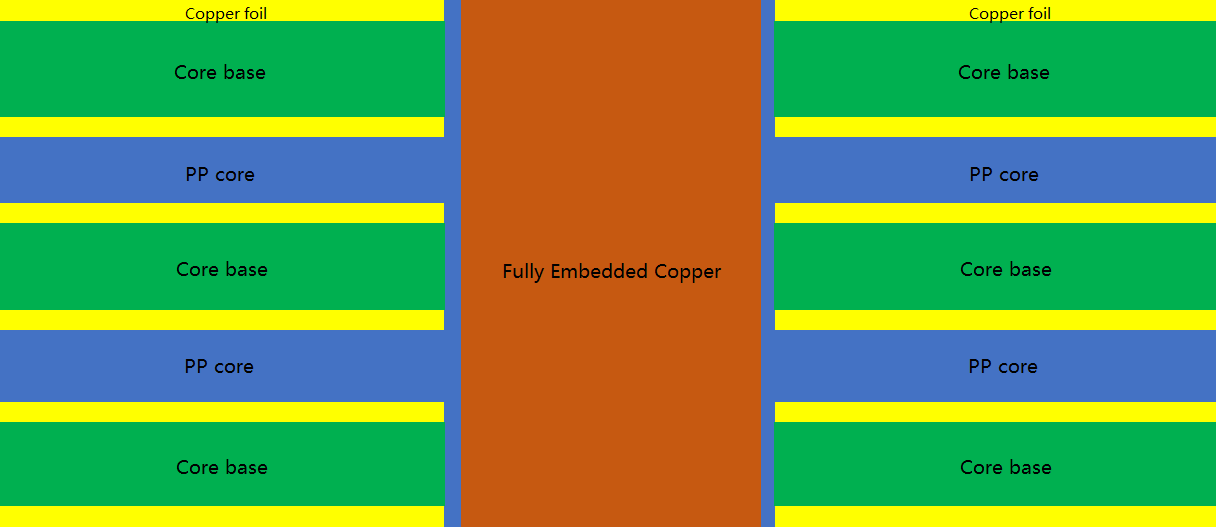

1. Fully Embedded Type

In this design, the copper block is completely enclosed within the PCB layers. The top and bottom surfaces are covered with laminate and copper foil. This structure provides excellent mechanical protection and a smooth board surface.

Key advantages include:

- Better electrical insulation and insulation.

- Flat surfaces are ideal for multilayer integration.

- Increased durability for vibration-prone environments.

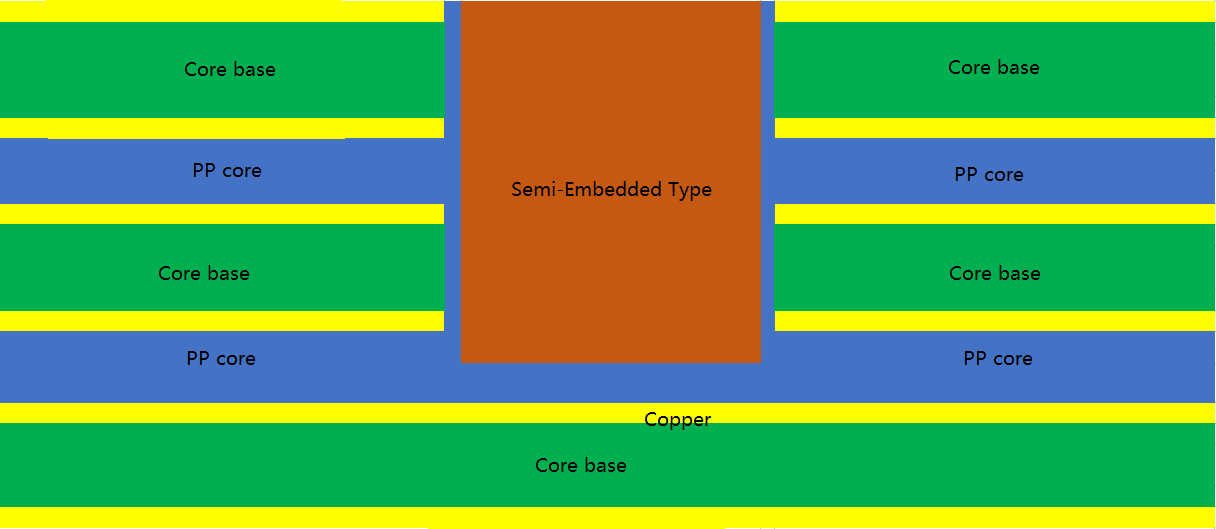

2. Semi-Embedded Type

In semi-embedded designs, part of the copper block is exposed or protrudes slightly from the surface of the board. This configuration allows direct contact with high-temperature components, such as power modules or metal housings, thereby increasing heat transfer.

Benefits include:

- Faster thermal conduction.

- Ideal for heat sinks or direct bonding applications.

- Reduced thermal resistance for high current circuits.

Choosing between fully embedded and semi-embedded structures depends on the application power level, heat load and assembly method.

Why Use Embedded Copper Busbar Technology?

Modern electronic devices are becoming smaller, more powerful and more efficient — and these trends increase the challenges of managing heat and current density. Embedded copper busbar PCBs are the solution to this challenge.

1. Superior Heat Dissipation

The thermal conductivity of copper is approximately 400 W/m·K, which allows it to absorb and disperse heat quickly. By placing a copper block directly under hot components, this board dissipates heat faster, preventing hot spots, and extending component life.

2. Increased Current Carrying Capacity

High current devices such as inverters and converters often handle tens or hundreds of amps. Embedded copper blocks create thicker and wider current paths, minimizing resistance and voltage drop. This increases system efficiency and reliability.

3. Space Saving Design

Rather than adding a bulky external busbar, engineers can embed the copper directly inside the PCB. This approach reduces assembly complexity and makes the entire system more compact — especially useful for electric vehicle power modules and industrial drives.

4. Better Mechanical Stability

The embedded structure strengthens the PCB mechanically, reducing warping and increasing resistance to thermal shock. This is important for applications where temperature changes and vibration occur frequently.

5. Simplified Assembly

With the busbar integrated into the PCB, component installation is easier. This also eliminates the additional soldering or mechanical bonding steps that external copper rods require.

Embedded Copper Busbar PCB Applications

The use of embedded copper busbar technology has grown rapidly in high-power industries. Here are some common examples:

- Electric Vehicles (EV)

- Battery Management System

- DC-DC inverter

- Renewable Energy Systems

- Solar Inverter

- Wind Power Converter

- Industrial Electrical Supply

- Aerospace and Defense

- Railway and Transportation Electronics

Each of these sectors values efficiency, thermal reliability, and mechanical strength — qualities that embedded copper PCBs consistently deliver.

Design Considerations Engineers Should Know

Despite the advances in embedded copper technology, design success still depends on key parameters:

- Copper Thickness: Typically ranges from 0.5 mm to 3.0 mm; Thicker copper increases conductivity but affects stack balance.

- Slot and Block Size: The minimum recommended size is 3×3 mm for stable laminates.

- Hole-to-Edge Distance: Keep at least 1.0 mm to prevent delamination.

- Material Selection: Use PP type FR-4 or a validated special material with good resin flow. Avoid the Rogers 4450F.

- Stacking Planning: Always use a core-to-core laminate structure to ensure strong adhesion and proper pressure distribution.

Designing a busbar PCB requires collaboration between electrical engineer, mechanical designer, and PCB assembler. Early involvement of manufacturing experts helps optimize costs, yields and performance.

How Embedded Copper Busbars Improve Thermal and Electrical Performance?

Let’s consider a simple example. Imagine a power inverter that handles 80A continuous current. A standard 2oz copper PCB trace would require a very wide path to safely handle that current. That’s not practical on a compact board.

By embedding a Copper block 2 mm thickYou can achieve the same current capacity in a fraction of the space, while creating a thermal path directly beneath the power semiconductor.

Tests show that boards using embedded copper busbars can reduce temperature rise by 30–40°C under the same load conditions compared to conventional designs. It directly translates to longer component life and increased efficiency.

Challenges and Considerations When Producing Busbar PCBs

Despite its great benefits, embedded copper PCB designs require precise process control. Factors such as laminate pressure, resin flow, and alignment tolerances must be carefully monitored.

Manufacturers must also ensure:

- Flatness between copper surface and laminate.

- There are no cavities or resin recessions near the copper edge.

- Reliable adhesion in high thermal cycles.

At Best Technology, we use core-to-core lamination, strict tolerance checks and real-time MES tracing capabilities to manage every stage. Each board is verified for height uniformity, dielectric strength and thermal reliability before shipping.

Why Choose the Best Technology for Embedded Copper Busbar PCB?

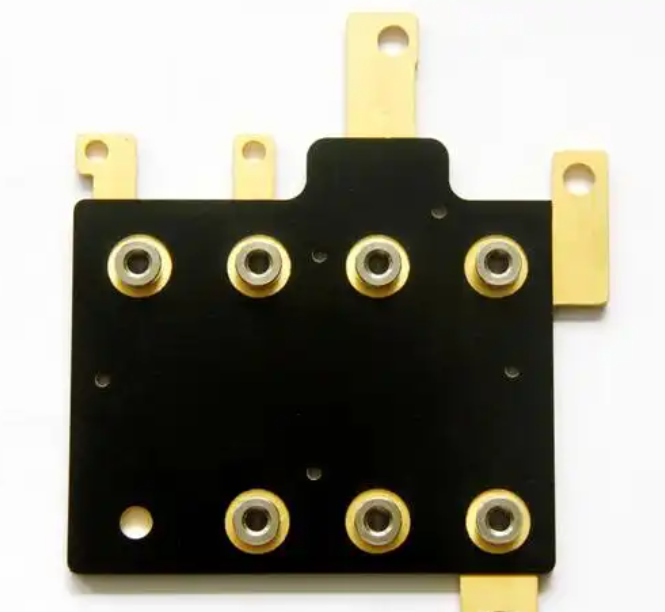

Best Technology specializes in advanced PCB fabrication for high current and thermal critical applications. Our embedded copper busbar PCBs are trusted by global clients in the power control, automotive and renewable energy sectors.

Here’s what sets us apart:

- Turnkey services from busbar PCB design, prototyping, testing to mass production

- ISO9001, ISO13485, IATF16949 and AS9100D Certified

- Various PCB materials such as FR-4, metal core, and ceramic-based boards.

- Mature busbar PCB manufacturing, whether you want fully embedded or semi embedded type.

- Each board passes thermal shock testing, cross-section inspection and IPC-6012 verification.

- A full traceability system ensures process consistency from materials to delivery.

When you need a partner for complex busbar PCB designs, our engineers support you from prototype to mass production with detailed feedback and optimized DFM solutions.

Conclusion

Embedded copper busbar PCBs represent a powerful evolution in PCB engineering — where electrical performance meets thermal reliability. By integrating copper busbars into the PCB, designers achieve a stronger, cooler, and more efficient system without adding bulk.

For engineers working in the fields of electric vehicle power control, industrial automation, or renewable energy, this technology provides a strong foundation for long-term success.

If you are planning to design a high current embedded copper PCB, talk to Best Technology. Our team of professionals can help you select materials, determine layout, and optimize copper structures for your performance goals.

Tag: Busbar PCB, copper busbar PCB, embedded copper busbar PCB

This entry was posted on Tuesday, October 21, 2025 at 18:14 and is filed under best PCB, best PCB, Design Guide, FAQ, Custom PCB. You can follow any responses to this entry via the RSS 2.0 feed. You can skip to the end and leave a response. Ping is currently not allowed.

News

Berita

News Flash

Blog

Technology

Sports

Sport

Football

Tips

Finance

Berita Terkini

Berita Terbaru

Berita Kekinian

News

Berita Terkini

Olahraga

Pasang Internet Myrepublic

Jasa Import China

Jasa Import Door to Door

Comments are closed, but trackbacks and pingbacks are open.