Cold solder joints are one of the most common reliability defects in PCB and PCBA assemblies, and continue to be a major source of intermittent failure in consumer electronics, industrial controls, medical devices, automotive modules, and aerospace hardware. At Best Technology, we see the long-term consequences of cold joints in failure analyzes coming from global customers—especially in assemblies that prioritize stable conductivity and mechanical strength.

With 19 years of PCBA production experience China and Vietnammedical-grade and aerospace-grade certifications, and MES-controlled SMT lines, we understand how cold solder joints arise, how to eliminate them, and how to engineer assemblies that remain stable throughout the product life cycle.

What Is a Cold Solder Joint?

Cold solder joints form when the solder does not melt or completely wet the component pads and wires. Instead of creating a unified bond, the solder cools prematurely or never flows properly, resulting in a dull, spotty, or uneven joint.

In the PCBA environment, cold joints are considered a process defect because they weaken the mechanical integrity of the soldered joint and create unstable electrical performance that degrades over time.

In high-reliability sectors—medical, industrial, aerospace—these defects are unacceptable and must be eliminated at their root causes: temperature control, surface condition, solder alloy behavior, and wetting characteristics.

Do Cold Solder Joints Still Work?

For a while, yes. Reliable, no. Cold solder joints may appear to work during a quick test, then fail:

- When the board heats up during normal operation

- When vibration or light mechanical stress occurs

- When humidity or temperature cycles change the contact resistance

- When the current load increases

This unstable behavior is what makes cold connections one of the most frequently misdiagnosed sources of failure. Many customers approach Best Technology believing they have a “component problem” or “firmware bug,” when the real cause is inconsistent solder metallurgy.

Symptoms of Cold Solder Joints

From a PCBA point of view, cold joints cause increased early failure under stress. Common symptoms include:

- Intermittent booting or power instability

- Flashing LED, display, or sensor readings are inconsistent

- Weak or noisy signal on the communication line

- Excessive heat around soldered components

- A board that only functions when pressed or tapped

- Modules that behave differently under temperature changes

During incoming quality analysis at Best Technology, we often find that unstable BGA bulbs, hand-soldered connectors, and TH pins are common locations for cold connections.

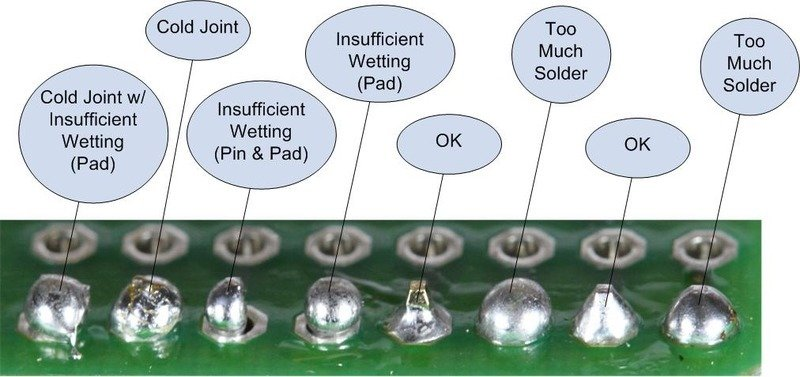

What is the Difference Between a Cold Solder Joint and a Good Solder Joint?

A good solder joint produces a smooth, bright, uniform joint that encloses the tin with full wetting.

Cold joints usually indicate:

- Dull or matte finish

- Crystalline or rough texture

- Break the ring around the lead

- Small gap between solder and pad

- Solder bubbles instead of flowing

Experienced technicians immediately recognize these visual cues as they indicate weak mechanical support and unstable electrical conductivity.

How to Identify Cold Solder Joints?

Both technicians and advanced PCBA manufacturers rely on several inspection methods:

- Bright, oblique light inspection to reveal dull or opaque surfaces

- Magnification to highlight cracks or gaps

- Gentle mechanical pressure to detect movement

- Thermal testing to expose changes in resistance under heat

- AOI or X-ray for lead-free and hidden joints

On Best Technology’s MES-controlled lines, each soldering step—including resoldering, wave, and selective soldering—is tied to a traceable profile, making it easier to isolate and prevent cold joints during future fabrication.

Are Cold Joints Acceptable?

No. Cold solder joints are never acceptable in professional electronics.

They violate:

- IPC-A-610 standard

- Reliability requirements

- Safety and quality regulations

Even in low-cost consumer electronic products, cold connections significantly reduce product life and reliability.

What Causes Cold Solder Joints?

Cold solder joints originate from several process or operator related factors:

- Insufficient soldering temperature

- The iron tip or nozzle is not able to conduct heat stably

- Oxidized bearings, tin or old components

- Solder paste expired or not stored properly

- Flux fatigue or inadequate flux coating

- Movement of components during cooling

- Large areas of copper absorb heat too quickly

- The reflow curve in SMT production is wrong

With our two factories in China and Vietnam, Best Technology maintains tight humidity control, paste storage, stencil management, and reflow calibration—significantly reducing these risks.

What Are the Risks of Cold Joints?

Cold solder joints give rise to cascading reliability issues:

- Intermittent electrical contact

- Stressed joints overheat

- Noise, distortion, or unstable signal

- Sudden shutdown during operation

- Premature component failure

- Total system outage in critical environments

In medical, industrial and aerospace PCBAs, even a single cold junction is considered a critical defect (CD level). Best Technology filters aggressively to ensure these defects never leave the factory.

How to Repair Cold Solder Joints?

Repairs are straightforward, but must be done correctly:

1. Clean the connection with isopropyl alcohol.

2. Apply quality flux to reactivate the surface.

3. Reheat the joint until the solder is completely melted.

4. Add a little new solder if needed.

5. Allow complete cooling without movement.

6. Visually inspect to ensure proper filleting and wetting.

For SMD components (QFN, BGA, LGA), hot air reflow ensures even heating.

How to Avoid Cold Solder Joints?

Prevention comes from controlled process engineering:

- Use calibrated, temperature-controlled soldering equipment

- Maintain cleanliness of components and PCB

- Follow the correct reflow temperature profile

- Apply flux or paste with proper wetting characteristics

- Preheat the heavy copper board

- Avoid vibration during cooling

- Use AOI/X-ray to verify solder integrity

- Implement operator training and certification

At Best Technology, these practices are embedded in the MES workflow, ensuring traceability and repeatability—from prototype to mass production.

FAQ About Cold Solder Joints

1. Can flux prevent cold solder joints?

Flux increases wetting, but without the proper temperature, cold joints still occur.

2. Can cold solder joints cause short circuits?

Yes. Cracks or partial bonds can create unwanted bridges.

3. Why are cold solder joints more common with lead-free solder?

Lead-free alloys require higher melting temperatures and tighter process control.

4. Can a multimeter detect cold solder joints?

Occasional, but intermittent faults often remain hidden until the board is heated or buckled.

5. Can reheating permanently repair a cold solder joint?

If the bearings and leads are clean and properly wetted, reheating will provide a permanent fix.

6. Do professional PCBA manufacturers still experience cold joints?

This is rare, but only because inspection systems, controlled processes, and trained operators keep solder quality consistent.

When to Consult a Professional or PCBA Manufacturer?

If your board exhibits repeated failures, unstable behavior, or many questionable connections, a professional evaluation is the safest option. Best Technology supports global customers by:

- Internal FA (failure analysis)

- X-ray examination and AOI

- Controlled reflow soldering

- Medical level and aerospace level quality system

- MES tracked production in China and Vietnam

Whether you need a prototype repair, DFX recommendation, or full PCBA build, our engineering team ensures solder reliability at every stage of the product life cycle.

Tags: cold solder joints, causes of cold solder joints, meaning of cold solder joints, smt cold solder joints, symptoms of cold solder joints

This entry was posted on Friday, January 2, 2026 at 18:18 and is filed under best PCB, best PCB, FAQ, PCB News, PCBA, SMT Technology. You can follow any responses to this entry via the RSS 2.0 feed. You can skip to the end and leave a response. Ping is currently not allowed.

News

Berita Teknologi

Berita Olahraga

Sports news

sports

Motivation

football prediction

technology

Berita Technologi

Berita Terkini

Tempat Wisata

News Flash

Football

Gaming

Game News

Gamers

Jasa Artikel

Jasa Backlink

Agen234

Agen234

Agen234

Resep

Download Film

Gaming center adalah sebuah tempat atau fasilitas yang menyediakan berbagai perangkat dan layanan untuk bermain video game, baik di PC, konsol, maupun mesin arcade. Gaming center ini bisa dikunjungi oleh siapa saja yang ingin bermain game secara individu atau bersama teman-teman. Beberapa gaming center juga sering digunakan sebagai lokasi turnamen game atau esports.

Comments are closed, but trackbacks and pingbacks are open.