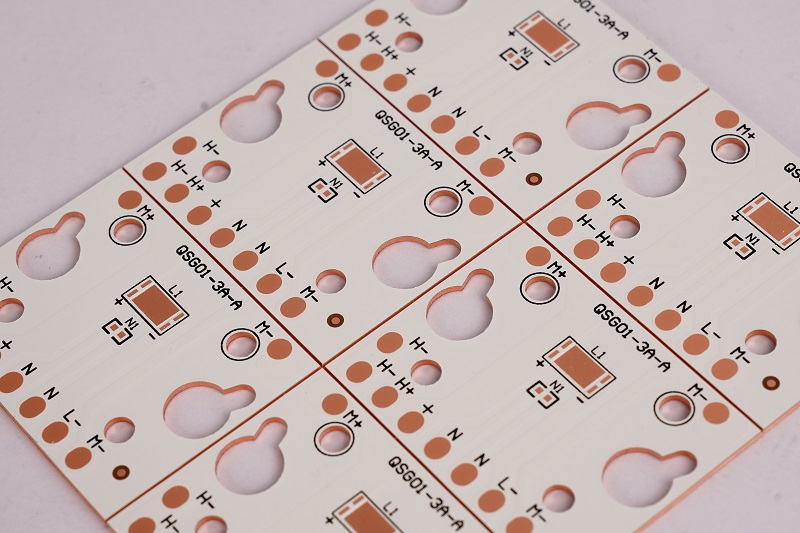

The thermal conductive PCB is the heart of hot control in modern electronics. In this blog, we especially discuss the definitions, materials, thermal conductive PCB applications, and where to get a fast thermal conductive PCB from the prototype.

Have you ever suffered from this bad headache?

- Have you ever experienced terrible thermal management problems?

- Have you ever faced complexity in the selection and material processes?

- Have you ever struggled by balancing a fast prototype and mass production?

- Have you ever worried about the lack of thermal management solutions?

There are several optimal ways to deal with the above problems.

- Applying MCPCB thermal management solutions, which do the heat from the circuit board to the heat sink.

- Using the thermal conductive dielectric material to improve the ability of PCB thermal management.

- Optimizing the prototype and fast fabrication. Using a rapid prototype development process to shorten the development cycle, reduce design changes, and manufacturing complexity through modular design.

- Improve thermal management design. For example, using thermal analysis tools to carry out thermal management design, and follow the rules of thermal management design to improve the efficiency of thermal management in the end.

The best technology is one of the best PCB manufacturers in China, providing the thermal conductive PCB, IMS PCB, Aluminum Core PCB, Busbar PCB, heavy copper PCB, HDI PCB, Ceramic PCB, and more. If you want to ask about PCB or PCBA, just write an email to us at sales@bestpcbs.com.

What does the thermal conductive PCB mean?

The purpose of the thermal conductive PCB design is to do heat from components to maintain a stable circuit. The thermal conductive PCB is different from the general PCB. It uses the high thermal conductivity rate of PCB material or metal core. The heat is done through a copper layer, thermal conductive VIAS, or metal substrate. This design if it is useful for reducing the temperature of the chip and extending the life of the device.

What is thermal conductivity FR4?

Low FR4 thermal conductivity. In general, only about 0.3 W/M · k. For low power devices, FR4 is a good choice. However, in high power LEDs, car modules or RF circuits, FR4 cannot eliminate heat effectively. That is why the designer moves towards the metal core board, ceramics, or other high thermal conductivity PCB materials. Many customers will meet some problems because they still use FR4 even in high heat loading situations. The best technology helps by suggesting better materials during the initial design stage.

What is the highest thermal conductivity PCB material?

Among all the options, the thermal conductivity of copper is the highest at nearly 400 W/M · k. However, PCB copper is heavy and expensive. Aluminum is more cost efficient, and has good thermal conductivity, lighter weight. Ceramics such as aluminum nitride are also popular for their stability and high thermal PCB material values. It is good to know that engineers will choose the appropriate material based on costs, weight, and application.

What do the thermal conductive bands do for metal core PCB manufacturers?

Thermal conductive bands are widely used with metal core PCB producer solutions. It is able to bind components or heat sinks to the surface of the board. This brings benefits from increasing contact and reducing heat resistance. This small process gives a board of benefits through heat dissipation testing, and with the benefits of cost efficiency. It is very important to note that many customers have delayed the project because their heat dissipation testing failed. The best technology uses the thermal conductive tape, and you will enjoy the benefits of short waiting times and better stability.

What is the connection: thermal conductive PCB, PCB thermal resistance?

The link between the thermal conductive PCB and the thermal resistance of the PCB is direct. PCB thermal resistance refers to the efficiency of heat transfer between layers. Lower PCB thermal resistance, faster heat dissipation. The thermal conductive PCB can reduce hot spots, which promote the benefits of stability, and higher power density. Therefore, during the prototype, PCB’s thermal resistance parameters are key elements that are highly considered by customers.

How do you use a PCB thermal conductivity calculator when choosing the thermal conductivity PCB material?

PCB’s thermal conductivity calculators help predict how heat flows through materials. Input thickness, copper area, type of material and other parameters by engineers, then the tool will present the results. In this way, errors will decrease. However, it is common to find out that customers do not have time to do a dual inspection. By using a calculator, the best technology engineer helps save time and reduce risk by providing earlier guidance.

Why is the filler of the thermal conductive gaps important for high thermal conductivity PCB material?

Filling thermal conductive gaps bridge the air gap between parts and boards. The air will isolate the heat transfer. But the gap filler is able to do heat efficiently. For high thermal conductivity PCB material, gap filling maintains smooth and efficient surface contact. If not, even copper or ceramic boards, the effect will be reduced. This is important for electronic power and LEDs in particular.

What is the thermal conductive PCB application?

Applications include LED lighting, electric cars, 5G equipment, satellite modules and industrial drive. In this application, heat is the most terrible enemy of performance. The conductive PCB which thermally manages heat in a state that does not increase a large heat sink. Because it reduces weight, which is useful and important for aerospace and cars. And customers hope to get a prototype quickly in general. The best technology can meet this kind of demand through flexible prototype services.

Where to get a fast thermal conductive PCB from the prototype?

This is a problem of congestion to find a suitable supplier. Because various companies have a very delayed shipping time problem or quality control that has no hope. The best technology provides faster paths. We promise to be tacky through the implementation of the MES system. In addition, we offer full quality assurance. Our factory is fully compatible with ISO 9001, ISO 13485, IATF 16949, AS9100D, UL, Reach, and Rohs Standards. Our company is to fully dedicate ourselves to conduct DFM analysis, review thermal design problems during the prototype, so customers get not only our fast prototype but also professional solutions and can be applied by us. In this way, we can speed up the market entry time and reduce the cost of re -work.

In short, for electronic products, heat dissipation is needed. Each process decides the final performance, from the selection of material to the shipping prototype. We know that some customers often suffer from headaches for shipping time that is too hot or long. The best technology to solve customer headaches through a fast thermal conductive PCB prototyping, professional technical support, and strict quality management. For those who are looking for trusted conductive PCB partners, the best technology is ready to help. Warm welcome to contact us via sales@bestpcbs.com For our very professional support.

Tag: thermal conductive PCB

This entry was posted on Thursday, August 28, 2025 at 10:15 am and was submitted under the best PCB, BestTPCB, MCPCB, PCB Core Metal. You can follow any response to this entry through RSS 2.0 bait. You can jump to the end and leave a response. Pinging is currently not permitted.

News

Berita

News Flash

Blog

Technology

Sports

Sport

Football

Tips

Finance

Berita Terkini

Berita Terbaru

Berita Kekinian

News

Berita Terkini

Olahraga

Pasang Internet Myrepublic

Jasa Import China

Jasa Import Door to Door

Comments are closed, but trackbacks and pingbacks are open.