The performance of embedded copper busbar PCBs depends not only on the thickness or geometry of the copper but also on the surrounding environment. The stack material and configuration are the invisible foundations that determine whether boards will stay level, bond securely, and function properly under thermal stress.

When current and heat flow through a thick copper block, the prepreg (PP) material and surrounding core must withstand mechanical stress, resin flow, and temperature changes — all without warping or cracking. Slight discrepancies in the material or stack balance can cause delamination, resin overflow, or uneven surfaces.

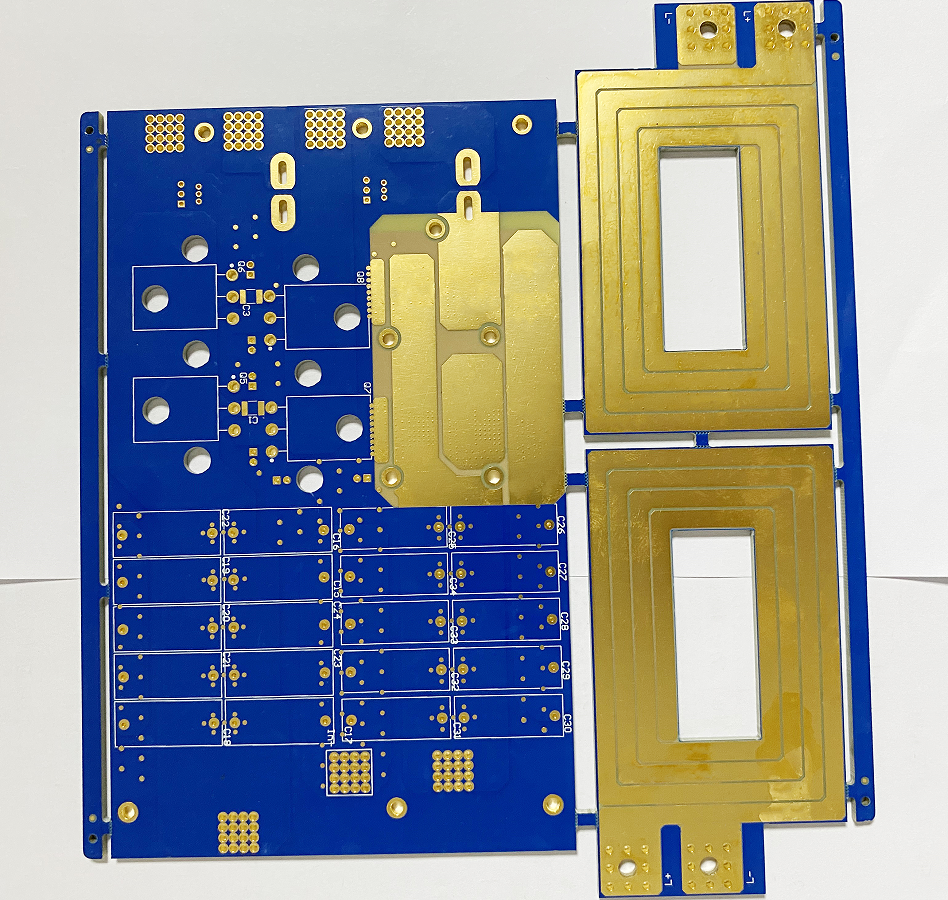

At Best Technology, we have perfected this relationship over many years of building embedded copper busbar PCBs for power electronics, new energy systems and electric vehicle modules. This guide summarizes the important principles in selecting materials and designing the ideal laminate layout for embedded copper applications.

Why is Material Selection Important in Embedded Copper Busbar PCBs?

Unlike standard multilayer PCBs, embedded copper designs involve large differences in material stiffness, density, and thermal expansion. Copper is dense and stiff, while FR-4 and PP are lighter and more flexible. During lamination, heat and pressure combine these materials into a single structure.

If the materials are not suitable, stress will build up around the copper area. This can result in:

- Resin cavity near copper corner.

- Uneven lamination pressure.

- Localized curvature after cooling.

Using the right prepreg and core ensures the resin flows properly, fills gaps and bonds firmly to the copper surface. This also ensures the copper remains perfectly aligned within the structure.

Understanding Core-to-Core Lamination Principles

One of the golden rules of embedded copper busbar PCB design is to use core-to-core lamination. Unlike conventional PCBs that may use copper foil on the outer layer, embedded copper structures require the strength and precision of core-based laminates to prevent warping. Here’s why:

- Copper foil is too thin and flexible. When combined with a thick copper block, it results in uneven pressure.

- The core material is dimensionally stable. They maintain thickness uniformity and resist deformation under high pressure.

- Core-to-core bonding ensures the copper block is tightly covered by a solid layer, rather than loose foil and resin.

This method produces a stable, tightly bound sandwich structure — perfect for high-current circuits.

Selection of Core Materials

The core material provides mechanical strength and dielectric isolation. In embedded copper designs, the core also serves as a stable base for copper slot milling and lamination.

Recommended Ingredients

- FR-4: The most widely used and validated material. Excellent mechanical strength and cost-effective for mass production.

- TU-872SLK, M6, SH260, FR-27, FR-28: These high performance materials can also be used, but require non-standard validation.

- Avoid PTFE: Too soft for polishing and laminating; can change shape when pressure is applied.

When polishing embedded areas, a harder surface is required to remove resin overflow without damaging the board. FR-4 performs best here, offering the perfect combination of hardness, stability and adhesion to copper.

Prepreg (PP) Material Selection.

Prepreg, or PP, acts as a bonding medium and gap filler between cores. It is responsible for flowing into the small spaces around the copper block during lamination and then hardening to create a strong bond.

For embedded copper PCBs, resin flow is critical. Low flow materials can cause weak bonds or trapped air.

Main Guidelines for PP Selection

- Use at least two PP sheets between each pair of layers.

- Choose PP with a high resin content to ensure proper filling.

- Recommended Type: Two layers of 1080PP high resin.

- Other acceptable types: 106, 3313, 2116, 7628.

- Avoid: Rogers 4450F (poor resin flow and weak bond strength).

Why High PP Resin?

Because the copper block is dense and has no pores, the resin must flow into every microscopic crevice along the copper edge. High resin PP fills these spaces more effectively, creating full contact and minimizing voids.

If the resin cannot flow freely, the interface between copper and PP can delaminate due to heat cycling.

Matching PP and Core for Proper Resin Flow

The combination of PP and core thickness should complement the thickness of the embedded copper. If the copper block is too thick compared to the slot depth of the PP+ core, it will make the laminate surface uneven. Thickness Correlation Guide:

| Copper Thickness (mm) | Slot Depth (PP + Core) | High Copper Produced After Lamination |

| 0.5–0.6 | Same as PP + Core | Flat surface |

| 0.8 | 0–0.05mm thick | Slightly raised |

| ≥1.0 | 0.05–0.1 mm thicker | 0–0.075mm above the surface |

Maintaining this relationship ensures that the copper rises slightly after lamination, which helps transfer heat efficiently to the external components.

Resin Flow and Filling Behavior

During lamination, the PP resin melts and flows around the copper block. To achieve perfect filling, it must reach all the tiny cavities between the copper surface and the core.

Factors Affecting Resin Flow:

- Resin content: High resin increases flowability.

- Pressing temperature and time: Must be controlled to prevent premature drying.

- Pressure: Enough to press the resin into the gap but not so much as to damage the core.

- Slot size: Must leave 0.05mm clearance on each side for resin flow.

At Best Technology, engineers simulate resin flow behavior during the design stage to ensure complete copper encapsulation. Our lamination system monitors pressure and temperature profiles to maintain resin balance throughout the panel.

Copper Busbar PCB Stacking Design Rules

Balanced stacking prevents board warping and mechanical stress. If one side of the PCB is embedded with copper but the other side is not, the uneven copper distribution can cause warping.

To prevent this:

- Distribute embedded copper areas symmetrically if possible.

- Add a faux copper area on the opposite side for balance.

- Use anti-warping layout in lamination.

- Avoid placing support materials near copper beams.

If balance cannot be achieved, engineers can use two release films or controlled pressure zones during lamination to keep the board level.

Semi-Embedded vs. Embedded Stacks Fully Embedded

The stack design also depends on whether the copper is semi-embedded or fully embedded.

Fully Embedded Stack-Up

- Copper is completely enclosed between the cores.

- Flat surface after lamination.

- Ideal for multi-layer or signal-integrated PCB designs.

- Requires proper slot alignment on all core layers.

Semi-Embedded Stack

- One side of the copper block remains exposed or almost flush with the outer layer.

- Used when direct heat transfer is required (for example, under electrical devices).

- Must include at least one layer of slotless PP under the copper block to electrically isolate it from the bottom core.

Both structures rely on the correct thickness of PP resin to ensure even pressure and insulation between layers.

Avoid Common Lamination Problems

Even with the right materials, poor lamination practices can degrade performance. Here are common problems and how to prevent them:

| Problem | Possible Cause | Solution |

| Resin cavities around the copper | Low flow PP or slot fitting | Use high PP resin and add 0.05 mm clearance |

| curved page | Unbalanced copper distribution | Use symmetrical stacks or faux copper |

| Delamination | Poor adhesion or incomplete resin filling | Verify copper oxidation and PP quality |

| Resin overflows | Excessive resin content or pressure | Optimize the number of PPs and press parameters |

| Surface steps | Copper block is too high or low | Double check the slot depth vs copper thickness |

Each of these factors can be controlled through careful material selection and process adjustments.

Why is Rogers 4450F Not Suitable as a PCB Busbar Material?

Although Rogers material is known for its high frequency performance, Rogers 4450F PP is not suitable for embedded copper applications. The resin flow is too low, and the bond is weak with the copper block.

During lamination, the limited mobility of the resin causes voids and poor adhesion, thereby leading to delamination under thermal stress. Therefore, all Rogers 4450F PP designs require non-standard approval — and in many cases, alternative materials are recommended.

Dielectric and Mechanical Performance Requirements

Embedded copper PCBs must maintain strong dielectric strength even with thick copper parts inside. At Best Technology, we validate dielectric and mechanical properties through standard testing:

- Dielectric Strength: ≥ DC 1500V

- Thermal Shock Test: 288°C × 10s × 5 cycles, no delamination

- Surface Flatness: ±0.075mm

- Adhesion Test: No separation after skin strength evaluation

Using validated core and PP materials, this board can easily meet or exceed IPC-6012 performance requirements.

Engineering Tips for Material Design and Stack-Ups

1. Always confirm material compatibility at the beginning of the design stage. Some specialty laminates require testing before production.

2. Use two or more layers of high resin PP for stable laminates around copper.

3. Save slot clearance and copper height within the specified tolerance.

4. For mixed material design, check CTE (coefficient of thermal expansion) compatibility to avoid stress on copper limits.

5. Share your stack drawings with PCB suppliers DFM Verification.

In our next blog, we will share the whole process of making PCB busbarif you are planning a new busbar PCB design, contact Best Technology for expert support. Our team can help you select materials, verify manufacturing capabilities, and provide reliable results for even the most complex embedded copper structures.

Tag: PCB Busbar, PCB busbar design

This entry was posted on Saturday, October 25, 2025 at 09:33 and is filed under best PCB, best PCB, FAQ, Custom PCB. You can follow any responses to this entry via the RSS 2.0 feed. You can skip to the end and leave a response. Ping is currently not allowed.

News

Berita

News Flash

Blog

Technology

Sports

Sport

Football

Tips

Finance

Berita Terkini

Berita Terbaru

Berita Kekinian

News

Berita Terkini

Olahraga

Pasang Internet Myrepublic

Jasa Import China

Jasa Import Door to Door

Comments are closed, but trackbacks and pingbacks are open.