What is Operational Qualification (OQ) in Medical PCBA Assembly?

Operational Qualification (OQ) is documented evidence that each step of the medical PCBA assembly process operates reliably within specified and approved operating limits.

After Installation Qualification (IQ) ensures that equipment and systems are installed correctly, OQ focuses on more critical questions: does the process actually work as intended in controlled variations?

In medical electronics manufacturing, OQ represents technical core of process validation. This is where technical goals, manufacturing capabilities and regulatory expectations meet.

Why is OQ an Important Requirement for Medical PCBA Manufacturing?

Medical devices rely on electronic devices that must perform consistently over long lifetimes, often in safety-critical environments or continuously operate. Final inspection alone cannot guarantee this level of reliability.

OQ is very important because:

- Indicates that the assembly process is capable, stable, and repeatable

- Defining acceptable process windows rather than relying on nominal settings

- Reduces reliance on operator judgment

- Provides objective evidence for regulatory audits and OEM reviews

From a regulatory perspective, OQ shows just that Process risks are understood and controllednot found after the failure occurred.

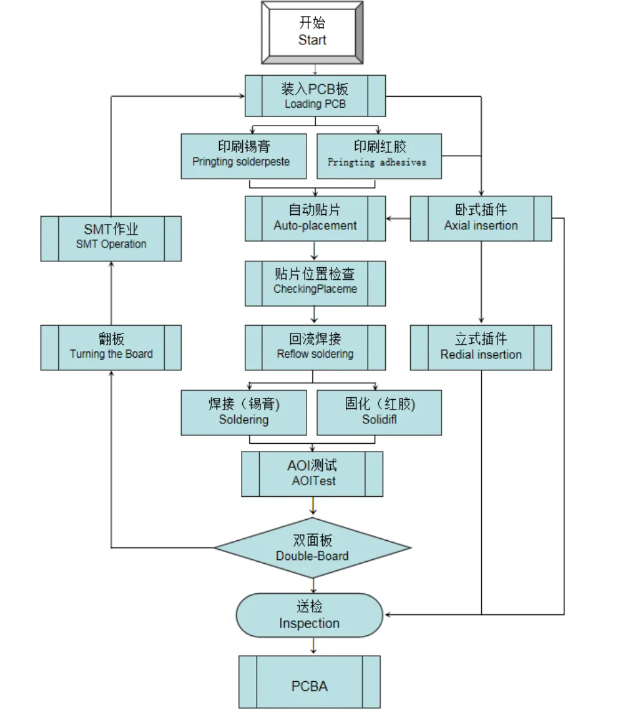

Which Assembly Processes Are Typically Validated During OQ?

In medical PCBA assembly, OQ typically includes all process steps that may impact product quality, reliability, or compliance. At (EBest Circuit) Best Technology, common OQ coverage includes:

- Solder paste printing: print speed, squeegee pressure, stencil alignment, and paste release consistency

- Component placement: accuracy across a wide range of package sizes, fine pitch components, and placement repeatability

- Reflow soldering: temperature profiles validated at minimum and maximum limits, including soak, peak and cooling zones

- Cleaning process: effectiveness in meeting ionic contamination requirements

- Conformal coating (if applicable): consistency of thickness, coverage, and curing parameters

- Functional and in-circuit testing: stability of results throughout the specified operating range

Each process is evaluated not only at nominal conditions but also near conditions upper and lower operating limits.

How Does OQ Define Windows Safe Processes?

One of the main goals of OQ is to build validated process window. Rather than asking whether a process was successful once, OQ asks whether the process continues to be successful when conditions vary within controlled limits.

For example:

- Can a solder joint remain reliable if the peak reflow temperature changes slightly?

- Does placement accuracy remain acceptable at different component densities?

- Does cleaning effectiveness remain consistent at different outcome levels?

By answering these questions, OQ transforms unknown variability into documented, acceptable rangeswhich is important for the reliability of medical PCBA.

Why is OQ So Important for Medical Electronic Equipment?

Medical PCBAs often involve:

- Fine tone and microtone components

- High density interconnection

- A mix of SMT and through-hole assemblies

- Sensitive analog, sensing, or signal conditioning circuits

These characteristics make medical electronics very sensitive to process variations. Small deviations can give rise to latent defects such as marginal solder joints or intermittent joints that pass inspection but fail in use.

OQ reduces this risk by ensuring that the assembly process remains stable even when operating close to specified limits.

How Does OQ Reduce Manufacturing and Patient Risk?

By validating process behavior within controlled variations, OQ helps prevent:

- Weak or inconsistent solder joints

- Excessive thermal stress or insufficient soldering

- Operator dependent results

- The process drifts over time

In medical applications, these issues are not just quality issues—they can also have direct impacts device safety, regulatory compliance, and patient outcomes. OQ provides technical evidence that these risks are being actively managed.

What Do Auditors and Medical OEMs Expect from OQ Documentation?

During audits or supplier qualification reviews, OQ documentation is often examined in detail. Auditors and OEMs typically expect to see:

- Process parameters are clearly defined and justified

- Evidence that the limits were deliberately challenged

- Repeatable and reproducible results

- Handling documented deviations or anomalies

Well-structured OQ records demonstrate that the manufacturer understands the process at an engineering level, rather than relying solely on empirical success.

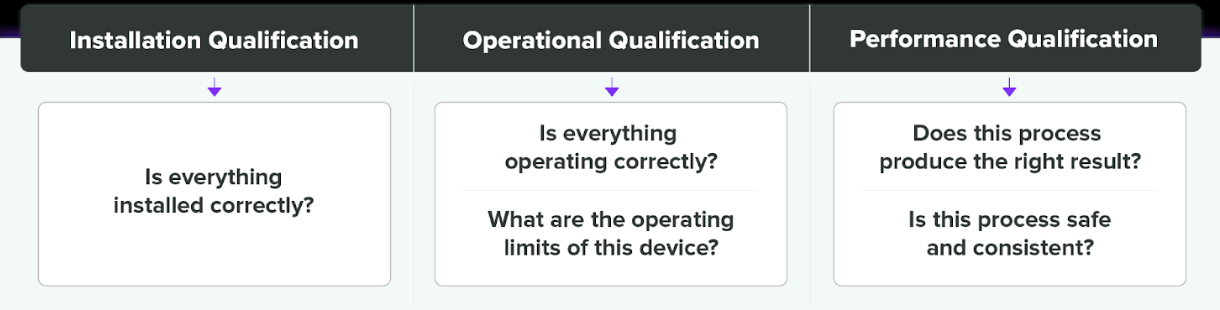

What is the difference between OQ and IQ and PQ?

Although IQ, OQ, and PQ are closely related, they each serve different purposes:

- IQ ensure that equipment and systems are installed correctly

- Okay confirms that the process operates reliably within specified limits

- PQ confirms consistent output under normal production conditions

OQ acts as bridge between installation and productiontranslating equipment capabilities into process control.

How Best Technology (EBest Circuits) Performs OQ for Medical PCBA Projects?

(EBest Circuit) Best Technology applies a structured OQ methodology tailored to medical electronics, including:

- The process limits are determined by the technique

- Controlled variation during validation runs

- Comprehensive data collection and analysis

- Documentation aligned with ISO 13485 expectations

This approach ensures that the medical PCBA assembly process not only works, but also works technically understandable and maintainable.

What Happens After OQ in Medical PCBA Validation?

Although OQ asserts that the process is capable, this has not proven long-term consistency in a real production environment. The confirmation was provided by Performance Qualification (PQ)that evaluates the stability of routine manufacturing across multiple lots and operators.

Related reading:

Performance Qualification (PQ) in Medical PCBA Production

To fully understand how OQ fits into a complete validation framework, it is also recommended to review:

Installation Qualification (IQ) in Medical PCBA Manufacturing

Together, these stages form a comprehensive, regulator-accepted approach to medical PCBA process validation.

Tag: medical pcba assembly, operational qualification, oq in medical pcba

This entry was posted on Saturday, January 10, 2026 at 10:05 am and is filed under best PCB, best PCB, FAQ, PCBA, SMT Technology. You can follow any responses to this entry via the RSS 2.0 feed. You can skip to the end and leave a response. Ping is currently not allowed.

News

Berita Teknologi

Berita Olahraga

Sports news

sports

Motivation

football prediction

technology

Berita Technologi

Berita Terkini

Tempat Wisata

News Flash

Football

Gaming

Game News

Gamers

Jasa Artikel

Jasa Backlink

Agen234

Agen234

Agen234

Resep

Download Film

Gaming center adalah sebuah tempat atau fasilitas yang menyediakan berbagai perangkat dan layanan untuk bermain video game, baik di PC, konsol, maupun mesin arcade. Gaming center ini bisa dikunjungi oleh siapa saja yang ingin bermain game secara individu atau bersama teman-teman. Beberapa gaming center juga sering digunakan sebagai lokasi turnamen game atau esports.

Comments are closed, but trackbacks and pingbacks are open.